Calibration and Inspection

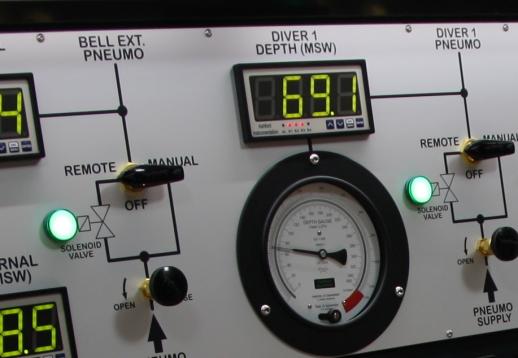

Gauge Calibration and Cylinder Inspection

Founded in 2006 by Mr John Florence, Westflo Technical Services now incorporated as a Fathom Systems company, have built a reputable track record in providing a value for money service primarily to the Commercial Diving sector. Offering on site instrumentation gauge calibration, certification and cylinder inspection services, Westflo are the preferred industry choice with regular and scheduled presence on a number of Dive Support Vessels and shore based facilities in the UK and Continental Europe.

Gauge calibration and cylinder inspection services offered are also suited to onshore plant facilities, marine sector vessels, offshore platforms and FPSO’s with Westflo already appointed as the service provider for several non-Diving Clients.

All calibration and inspection services are carried out by certified and competent personnel and in accordance with IMCA D 018 guidelines and recommended code of practice. All gauges are tested against certified test equipment traceable back to a national standard.